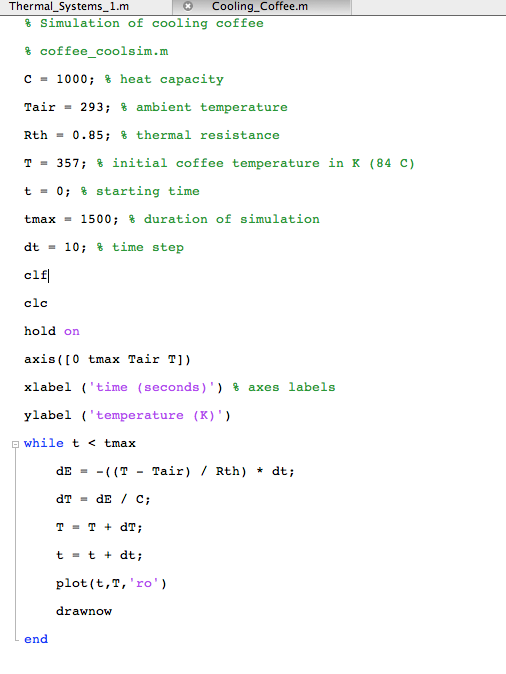

During class on Friday (4/25), Michelle worked on perfecting the claw while I worked on making the Rover's parts out of Delrin.

We decided to make our Rover appear similar to the Spirit/Opportunity Rover.

| Sprit/Opportunity Rover |

|

| Measurements |

|

| Foam core model of the box |

We made a last minute decision to try to piano-wire the box together, so we had to fix the solid works design to include ridges.

Saturday (4/26)

We finished up making changes to the solid works designs and cut them out using the laser cutter. Afterwards, I spent a great amount of time trying to piano-wire the box together. |

| Solid Works Drawing of the top of the box |

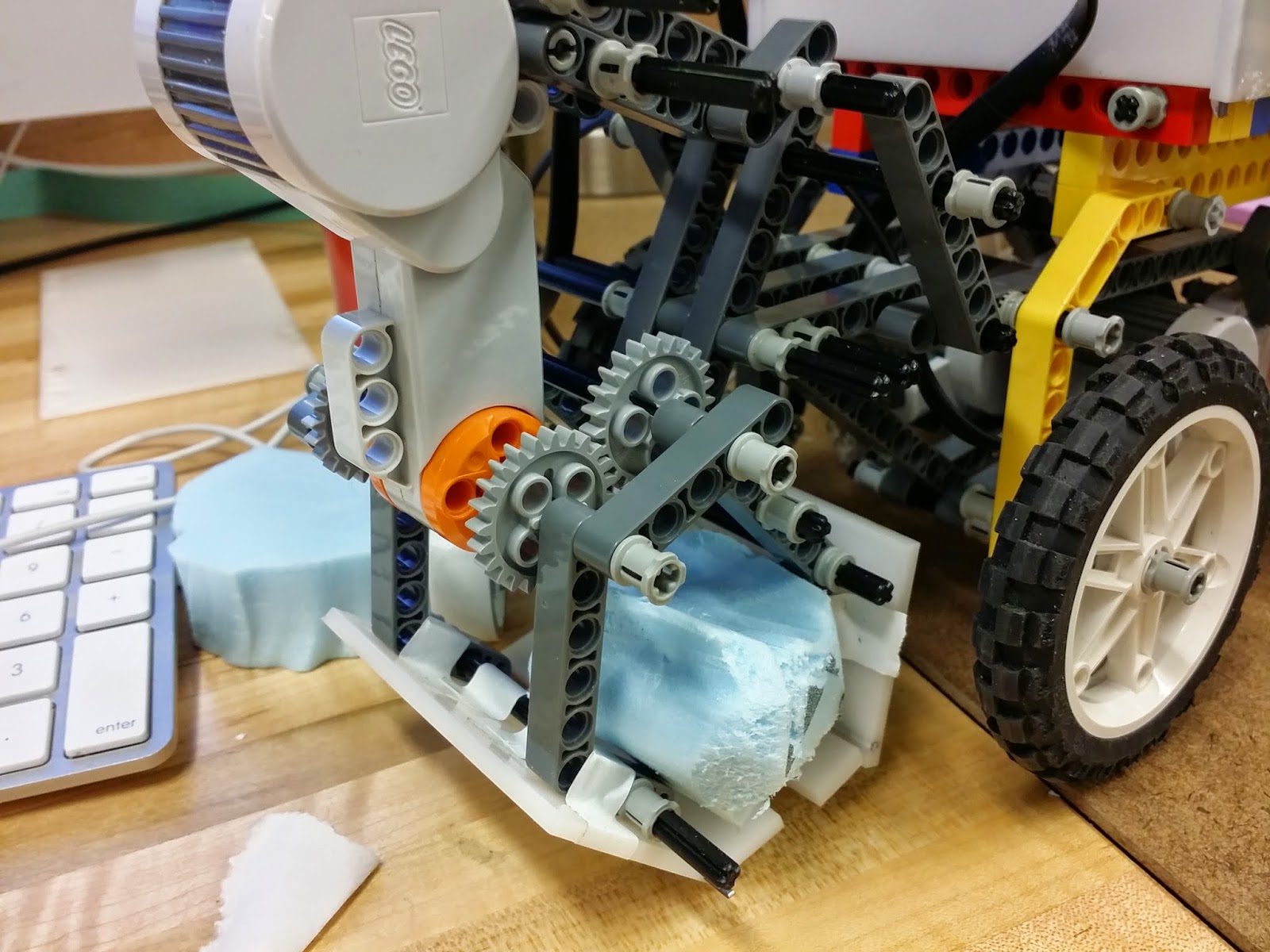

Meanwhile, Michelle perfected the claw so that the motor for the claw is facing perpendicular to the ground. After having worked on it for so long, we had to remove the flexible front wheels to attach the claw more effectively. We decided that it needed a sturdier claw to grab things more easily, so Michelle made a claw out of delrin and also piano-wired the parts together.

|

| Claw |

We also tried painting some foam rock pieces with spray paint:

After fixing the claw and attaching the box/solar panels, our Rover looked a lot more like the actual Rover!

Sunday (4/27):

I spent most of the day trying to decorate the Rover with metallic spray paint and building the terrain. We also programmed the Pico blocks and made different command blocks (forward, backward, left, right, open/close claw etc). Michelle tested out the Rover on the newly built terrain and tweaked the design of the Rover. She also filed a white Styrofoam into a ball for the claw to grab.Monday (4/28):

Michelle and I came into the studio at different times of the day to work on different parts of the project. I worked on the camera/phone stand using Solid works and assembled the pieces using glue. I also tried to connect the camera on the phone to the laptop.The phone stand fell off multiple times, so we used stronger glue to secure the stand.

After yesterday, Michelle realized that the Rover cannot run over our terrain because some of the rocks were too big. So I worked on cutting down the rocks so that the Rover would be able to run through it. Michelle worked on making a hill on the terrain and painting the terrain. The hill was problematic because the Rover could not run over hills that were too steep. Our original goal was to have the Rover go through hills and ditches, but we decided to include a single hill in the terrain. She also made finishing touches on the project while I worked on the poster for the presentation.

The purpose of the poster was to inform the audience about the Mars Rover and introduce them to our project.

(This is the mess I made in my room trying to make the poster)

This is how our Rover looked like:

t

t