We began Tuesday's class by taking about different feedback and control mechanisms. The most well known example of a feedback and control mechanism is the thermostat, which uses the bang-bang control and simply turns on/off the heater at full blast until the room temperature reaches the desired temperature. There are other feedback and control mechanisms that have more subtle controls and can be applied to different devices (such as the Google car).

Our SciBorg is a car-like device that is powered by the PicoCricket and can be programmed using the PicoBlocks to perform different tasks.

We started out by trying out different PicoBlock commands and playing around with different functions of the SciBorg. We made the SciBorg play sounds through the speaker, display different colored lights, and move back and forth.

As part of the official assignment, we made custom PicoBlocks that controlled the movement of the SciBorg. (Part a)

1. Forward

To make the SciBorg go foward, we simply use the motor on block and the power is set to 100 by default (which is full power)

2. Backward

Backward is pretty much the same as the forward with the exception of the reverse block added on before the motor on block

3. Brake

Stopping the SciBorg movement is also simple. It just requires a motor off block.

4. Spin-Right

In order to make the SciBorg Spin Right (clockwise), we set the power of motor b to a 100 and set the power of motor a to a 100 but in the reverse direction and turn on all of the motors

5. Spin-Left

Spinning left is very similar to spinning right, but with motor a going forward at full power and motor b going backwards at full power.

6. Bear-Right

To make the SciBorg bear right, we need to make the left motor (which is motor B in this case) go forward at full speed while the right motor is set at a smaller power. After we set the power levels, we turned on all of the motors and the car moved towards the right as it was moving forward.

Depending on the power level of motor a, we could control the amount it bears to the right. If we had a value closer to a 100, the car would only slightly bear to the right, and if we had a value that was closer to zero, it would almost turn to the right.

7. Bear-Left

For the bear-left block, we made the same sequence of blocks, but with the motor b set to a lower power than motor a.

For part b of the assignment, we tested out the shaft encoder. The shaft encoder uses a rotating plate and light to measure how much the wheel has spun and thus how much the device moves.

To start off, we programmed the SciBorg so that it would go forward until the counta for the encoder (starting at zero) is at 1000 and go backwards until the counta goes back down to zero

We started out by resetting counta just to make sure it is at zero. Then turned on the motor to allow the SciBorg to go forward and used the 'wait until' command to allow the counta to reach 1000. Then we braked the SciBorg and allowed it to move backwards and used the 'wait until' command to allow the counta to reach back to zero.

We used the reverse block at the end just so the SciBorg goes forward when we repeat the process.

For countb, we basically used the same blocks as counta

Using both the counta and countb command, we measured the difference between the starting point and the end point of the SciBorg's movement. I expected it to go forward and backward at the same distance, but there were some discrepancies.

For counta, there was a 3 inch difference between the starting point and the end point and for countb, there was a 6 inch difference.

I would think that this difference has to do with the different distances that each 'count' represents for counta and countb. Also, it seems like the forward and backward motion have different mechanisms in the SciBorg, because it moves more in the forward direction than the backward direction even with the same amount of count.

It seems like we are working with the 'control' side of the SciBorg by learning how to program different commands but not so much with the 'feedback' part. It would be interesting to incorporate the feedback mechanisms.

Friday, February 28, 2014

Wednesday, February 26, 2014

LEGO Racecar (Part 2 of 2)

Trial 6

After the 5th iteration, we wondered if we could lower the gear ratio a little bit in order to make our car go a little faster. We made a new car with 3 24-tooth gears that had a gear ratio of 27:1. We kept the same design as the previous car.It took a lot of thinking to get the 3 24-tooth gears to fit in a small space, and eventually, we had to move the motor off to the side of the car so the gears could fit. But the structure of the car was still stable.

|

| Left-5th iteration, Right-6th iteration |

The new car was not as organized as the previous car, but it was much lighter.

To compare the two cars' speeds, we did a side-by-side race of the two cars.

The new car was faster than the old car by 2-3 seconds. It took about 12-13 seconds with the new car to clear the finish line while it took about 14-15 seconds with the old car.

The Race!

At the beginning of class on Tuesday (2/25), we raced our cars as a class. Sunnia and I decided to only race our best car (which had a gear ratio of 1:27). Our time was 12.7 seconds, which was second fastest out of all the cars!In general, I think we were successful in building a stable yet fast car. If we were to make another iteration, we would try to make a better compartment for the weight since we noticed that it shifted slightly during our race. We would also try to make our car as slim and light as possible without making it structurally unstable.

Summary

Final Gear Ratio: 1:27

Gears Used: 3 24-tooth gears, 3 8-tooth gears

Sunday, February 23, 2014

LEGO Racecar (Part 1 of 2)

For this assignment we were finally able to use LEGOs from the LEGO cabinet! (It was my childhood fantasy to have all the LEGOs organized by parts)

The objective of the assignment was to make a race car out of LEGO bricks and gears. The car would have to carry a 1kg load and race in a 4m race track, and we were only allowed to use one motor to power the car.

We started out by thinking about the physics behind gears.

Starting out with the basics, we considered torque and angular velocity.

Given a force, the torque is the tendency of the force to rotate an object about an axis.The equation for torque is T(torque)=r x F = rFsin(theta). For gears, we are dealing with theta=90 degrees, so torque is equal to rF. r is the distance from the axis to the applied force. As r increases, torque also increases with the same amount of force. This is why it is easier to open a door when force is applied far away from the hinge.

Angular velocity (omega) is equal to v/r, meaning that it is inversely proportional to r.

The objective of the assignment was to make a race car out of LEGO bricks and gears. The car would have to carry a 1kg load and race in a 4m race track, and we were only allowed to use one motor to power the car.

We started out by thinking about the physics behind gears.

Starting out with the basics, we considered torque and angular velocity.

Given a force, the torque is the tendency of the force to rotate an object about an axis.The equation for torque is T(torque)=r x F = rFsin(theta). For gears, we are dealing with theta=90 degrees, so torque is equal to rF. r is the distance from the axis to the applied force. As r increases, torque also increases with the same amount of force. This is why it is easier to open a door when force is applied far away from the hinge.

Angular velocity (omega) is equal to v/r, meaning that it is inversely proportional to r.

| http://hyperphysics.phy-astr.gsu.edu/hbase/imgmec/vtord.gif |

So how is torque and angular velocity applied to gears?

Consider a small 8 tooth gear connected to a motor. Due to the very small radius of the gear, it rotates with a big angular velocity but with a small torque. If a 24 tooth gear is meshed to the 8 tooth gear, the 24 tooth gear would rotate with less speed, but with a greater torque. The gear ratio for this example is 3:1. This process of lowering speed and increasing torque is called 'gearing down'. The opposite process (increasing speed and decreasing torque) is called 'gearing up'. The ratio of torque and angular velocity change is proportional to the gear ratio. For the example, the gear ratio of 3:1 in the above example would increase the torque by 3 times and decrease the speed by 1/3.

After going through the basics of gears, Sunnia and I decided to try out several different gear ratios.

Trial 1

We felt very ambitious and decided to go for a big gear ratio for our first car. We had 3 24-tooth gears and 2 40-tooth gears, and 5 8-tooth gears to use as output gears for the gear train. The total gear ratio was 675:1 (3x3x3x5x5:1). Our gear produced a lot of torque but very little speed. With the weight on its back, the car could not move forward. Since the results were so abysmal, we did not bother to take a picture of the car.

Trial 2

For the second iteration, we decided to lower the gear ratio. We tried using 1 24-tooth gear and 2 40-tooth gears with 8-tooth gears connecting the big gears.The total gear ratio was 75:1 (5x5x3:1). The wheels were about 1.5inches in diameter and about 0.7inches in thickness. The design of the car was kept very simple and light, minimizing any unnecessary structures. The car was very slim, with the width being just wide enough to fit the 1kg weight.

We tested the car out on the 'race track' and it finished the race in 40 seconds.

Trial 3

After the second iteration, we decided to make a small structural change. Instead of using the smaller/thicker wheels, we decided to use the larger/thinner wheels so it would reduce the friction and increase the torque.

When we tested out the car on the track, the time was down to 25 seconds.

Trial 4

In order to make our car go faster, we tried out a smaller gear ratio. 2 24-tooth gears and 1 40-tooth gear was used and the gear ratio was 45:1 (3x3x5:1). We also made the car slightly shorter.

The car was dramatically faster than the previous iteration, and it took about 15 seconds for the car to go through the race track.

Trial 5

For the final iteration of our race car, we decided to focus on the aesthetics. We found a way to make the car even shorter by changing the orientation of the pico block. The car was just big enough to fit all of the necessary structures, including the weight. We also decorated the car a little bit in order to make it more pleasing to the eye. We also made the structure more stable by having more supporting LEGO bricks, so the car is not prone to damage.

The car was slightly faster than the previous iteration, it took just about 14 seconds to go through the 4m track.

(To be continued.....)

Tuesday, February 18, 2014

Engineering Seminar (2/12/14)

Dr. Kathleen Sienko gave a talk on Wednesday about her work in developing medical devices that can be used in underdeveloped countries with limited resources.

She began by explaining the limitations that developing countries face in terms of utilizing medical devices. The hospitals in developing countries often lack spare parts for the device, trained technicians, power, and manuals. So it is very important to design a device that is very intuitive, cheap, efficient, and work under scarce resources.

She talked about how male circumcision is a part of a ceremony in African communities and is known to reduce HIV rates but have a very high complication rate due to excessive bleeding and infections. Her team reached out to the African communities and communicated with the medical professionals in order to develop a safe device for circumcision. Dr. Sienko also talked about the lack of blood banks in African communities and how it can affect women who lose a lot of blood while giving birth. To develop a device that could re-transfuse the lost blood, her team of students developed a syringe-like device that could collect the blood and remove the clots for re-transfusion.

It was very interesting to realize that medical devices that hospitals use in the US is simply not efficient for use in developing countries. It is really difficult to think about these things during our day-to-day lives, so the seminar opened by eyes to medicine in developing countries. Also, I think it is very interesting how people from many different disciplines and backgrounds can cooperate to develop these devices that can aid the patients across the globe.

She began by explaining the limitations that developing countries face in terms of utilizing medical devices. The hospitals in developing countries often lack spare parts for the device, trained technicians, power, and manuals. So it is very important to design a device that is very intuitive, cheap, efficient, and work under scarce resources.

She talked about how male circumcision is a part of a ceremony in African communities and is known to reduce HIV rates but have a very high complication rate due to excessive bleeding and infections. Her team reached out to the African communities and communicated with the medical professionals in order to develop a safe device for circumcision. Dr. Sienko also talked about the lack of blood banks in African communities and how it can affect women who lose a lot of blood while giving birth. To develop a device that could re-transfuse the lost blood, her team of students developed a syringe-like device that could collect the blood and remove the clots for re-transfusion.

It was very interesting to realize that medical devices that hospitals use in the US is simply not efficient for use in developing countries. It is really difficult to think about these things during our day-to-day lives, so the seminar opened by eyes to medicine in developing countries. Also, I think it is very interesting how people from many different disciplines and backgrounds can cooperate to develop these devices that can aid the patients across the globe.

Well Windlass (Part 3 of 3)

Assembling the pieces

We used most of the class time on Friday (2/14) to assemble our parts. We first cut out our Delrin rod using a band saw. We cut 3 4cm pieces and two 10cm pieces.Then we used the drill press to piano wire the roofs together and also the supports.

We used a running-fit for the roof using a 1/16in wire and a tight-fit for the supports also using a 1/16 wire. It was a bit of a challenge to get the piano wires to properly fit into the holes that we drilled, but after we successfully wired our pieces, it was very strong and sturdy.

|

| Final Well Windlass |

Testing out the product

After we assembled our windlass, we attached a string to the 1L soda bottle, secured the other side to our wheel, and tested out the windlass.The soda bottle was surprisingly heavy, but we could get the bottle to lift up to the top of our roof, which is about 17cm.

Even though the wheel rotated smoothly and was secured tightly onto the support, the soda bottle was heavier than we had expected, and some bushings became a little loose if we did not turn the wheel properly. However, the device spanned the 12cm gap and the triangular shape made it extremely stable.

If we could make another iteration, I would try to make another small wheel (or more of a pulley) at the top of the roof so the friction between the string and the delrin would be lower, making it easier to lift up the soda bottle. I would also try to make a better handle for the wheel.

Thinking a little about the definition of work, we know that with a given amount of work, if the displacement is bigger, the force applied is smaller. Applying this principle, we could have made the wheel a little smaller so that it would have to revolve around more times (increased displacement) but we could apply less force when lifting the soda bottle.

The reason that we made the wheel this size (7cm in diameter) was because we wanted to turn the wheel a fewer number of times than if we had a small wheel. It would be good to find the perfect, balanced size for the wheel taking these two factors into consideration.

Overall, the project was a great way to apply the fastening and attaching techniques and gave me a chance to think about different principles that we learned in mechanics.

Material Usage

Delrin Rod- Three 4cm rods

- One 10cm rod

- One 15cm rod

- TOTAL: 29cm (under the limit)

Delrin Sheet (3/16 thickness)

- Roof: about 312 cm^2 for both roofs (It's actually slightly less, but I estimated)

- The support for the wheel and one of the support bars were cut out from the roof

- Wheels: 38.47 cm^2 for each wheel, 76.94 cm^2 for both wheels

- Support: 17cm^2

- TOTAL: 312+76.94+17=405.94cm^2 (under the limit)

String

- 120cm

Monday, February 17, 2014

Well Windlass (Part 2 of 3)

Making Test Pieces

In order to test out different fastening and attaching methods that we are using for the windlass, we made some test pieces using solid works. |

| Test Piece for Delrin Rod |

|

| Press Fit Test Piece |

We wanted to test the tight fit and the loose fit for the Delrin rod in order to figure out the perfect dimensions. In order to do this, we used a caliper to measure out the diameter of the delrin rod and made a test piece with different sized holes to test out the fit. We found out that for the Delrin rod of diameter 6.32mm, a diameter of 6.28 was good for a tight fit and a diameter of 6.5 was good for a loose fit.

We also made a test piece for the press fits. We used a caliper to measure the thickness of the material that we were using, and and made notches with varying widths. After several tries, we found out that for the material thickness of 5.48mm, the notch width of 4.32mm was good for a tight press fit.

|

| Test Pieces |

We also decided to make small test pieces of the roof and supports of our windlass in order to practice using the piano wire. For the roof, we figured out that we needed to make our notches deeper in order for the two sides to be at an angle that we wanted.

|

| Roof Test Piece |

|

| Support Test Piece |

Printing out the pieces

After making adjustments based on our test pieces, we decided to go ahead and draw our actual windlass parts into solid works.

In order to save material, we actually carved out part of our roof for some of the parts that we needed.

|

| Solid Works Drawing of the Wheel |

|

| Solid Works Drawing of the Roof |

|

| Printed Parts |

(To be continued....)

Exploring Mechanisms

| Multiple Straight Line Drive (http://kmoddl.library.cornell.edu/model.php?m=468&movie=hide) |

In preparation for the next project, I looked at many different mechanisms that converts circular motion to liner motion (or something similar to a linear motion).

There were many interesting mechanisms listed on the Kinematic Models for Design Digital Models website (http://kmoddl.library.cornell.edu/model.php?m=reuleaux), but one that struck out to me was the multiple straight line drive.

When I first saw this mechanism, my initial reaction was that it looked very similar to a mechanism for a car engine. However, while the car engine uses the energy from the gasoline combustion to convert the linear motion of a piston to a rotational motion of the crankshaft, the multiple straight line drive is converting a circular motion of the gears to a linear motion of the piston.

The multiple straight line drive was particularly interesting to me because it converts circular motion into a simple harmonic motion, and the piston moves in a perfectly linear path rather than veering off to the side.

As seen in the above picture, the axis of the smaller gear is secured onto the brown circular board and as the board moves in a circle (possibly with the help of a motor) the small gear meshes with the external gear. The external gear spans the outer rim of the circle but is not part of the rotating board.

As the small gear moves in a circle around the external gear, the joint that attaches the piston to the small gear moves up as the small gear reaches the top of the circle and moves down as the small gear reaches the bottom of the circle.

As seen in the left picture, the piston moves up a distance that is equal to the diameter of the external gear.

I also noticed that there were particular conditions that need to be met in order for this mechanism to work. The diameter of the external gear must be exactly half of that of the external gear in order for the piston to move up and down in a straight line.

Since the diameter of the small gear is exactly half of that of the external gear, the joint that is attached to the small gear always lines up with the center-line of the external gear (indicated by a green line in the right figure) This allows the piston to move along the center-line in a straight motion.

If the diameter of the small gear was greater than what it is now, the piston would not move up and down in a straight motion. I have made a simplified diagram depicting this:

As seen in the above figure, the piston is slanted if the diameter of the small gear is not exactly half of that of the external gear.

For devices powered by motors (or maybe wheels), this mechanism can be used to convert the circular motion into linear motion. For example, devices like the sewing machine is powered by a motor but a linear motion is needed for the needle to move up and down. This mechanism also reminds me of a water mill, where the circular motion of the wheel is converted to linear motion in order to process flour.

Friday, February 14, 2014

Well Windlass (Part 1 of 3)

For our second assignment, we were asked to design a well windlass that spans a gap of 12cm between two tables and has a crankshaft that can be used to lift a 1L bottle of soda 10 cm above the table. We were limited to using 500cm^2 of Delrin sheet and 50 cm of Delrin rod for our final model.

Brainstorming

Kirsten and I decided to work together for this assignment and came up with some ideas for our windless design.Our first idea was the trapezoidal windless, where we would have two trapezoids as support and the Delrin rod going through the middle. However, this idea did not seem structurally stable.

The second idea was the pyramid windless, where we would have triangles as the support and a short piece of Delrin rod running through the middle for the string to wrap around in. We thought using a shorter piece of Delrin rod will decrease the deflection. However, with a flimsy and thin Delrin rod, it would take a lot of effort to pull up the soda bottle with this model.

Our third idea was to make a wheel using the Delrin rod and have the string wrap around it. This would drastically decrease the amount of rotations the crankshaft would need to make in order to pull up the bottle. Since we are making the wheel with multiple Delrin rods, the force from the bottle (mg) would be distributed amongst the rods rather than having one Delrin rod bear all the force. Also, our roof-like triangular shape provided structural stability because it has less degrees of freedom than a trapezoid shape.

One problem we ran into with the wheel model is figuring out the best positioning of the wheel. If the wheel was on top of the roof, it would be awkward to turn the crankshaft because the person would have to reach up to the top of the roof. We then had an idea of attaching the wheel directly to the roof, but that also had some problems because it would be hard to have the wheel secured onto the roof while still being able to rotate it around the axis.

|

| Brainstorming |

Finally, we decided to have a support for the wheel that would be press-fitted onto the roof. This way, we could turn the wheel without having to worry about the wheel falling out.

|

| Rough Sketch of the Model |

Based on our sketch, we wrote out some dimensions of the parts before making the foam core model.

|

| Dimensions |

Making a Foam Core Model

| |

| Foam Core Model |

(To Be Continued.......)

Sunday, February 9, 2014

Fastening and Attaching (2/4/14)

During class on Tuesday, we learned about the different fastening and attaching techniques in preparation for the upcoming windless assignment.

Piano Wires

Our group first learned about using piano wires to attach two pieces of delrin together. Using a wire cutter, we cut piano wires of different diameters and learned to measure the diameters using a caliper. It was my first time using a digital caliper, so I thought it was very convenient compared to the non-digital ones. We also measured the diameter of the drill bits in order to determine what size we would use for a particular piano wire. Depending on how tight we want our wires to fit, we would adjust the size of the drill bits. Then, we were given the opportunity to try drilling a hole into a piece of delrin using the drill press and fitting a piano wire through the hole also using the drill press.

The piano wire technique is great for making hinges and joining corners. One precaution that we need to take when using this technique is to make sure that the holes are lined up perfectly and that the wire is mostly straight. Also, we need to be careful when using the drill press and slowly drill little by little.

Press Fit

The second technique we learned was press fitting. Press fitting is another technique that is used when joining delrin pieces together. We first need to measure the width of the delrin we are using with a caliper. For a tight fit, there notches need to accurately cut using the laser cutter and the height of the notches need to be about 0.005 inches taller than the width of the delrin. The fitting can be removed using pliers, but not easily with just bare hands.

My partner and I tried cutting small test pieces using the laser cutter, but our notches were too small. It takes very accurate measurements for the press fit to work perfectly, but it is one of the methods that require the least amount of technical work.

Heat Staking and Bushings

Lastly, we were introduced to heat staking and bushings.

Heat staking is simply melting the delrin onto another piece of delrin and attaching the two pieces together. Using a laser cutter, a square hole is cut onto a piece of delrin and another piece is cut so that there is a part that could fit through the square hole. Then, using a heat stake that is set to about 400 degrees F, we melt down the delrin until it is completely melted onto the other piece of delrin. Then we turn off the heat stake and use the air valve to cool down the delrin for about 50 seconds.

This is a great technique for joining pieces of delrin, but it would be difficult to join edges in an angle due to the nature of the machine.

In order to make our windless using rods, making bushings is an absolutely useful technique. Similar to the press fit, we need to measure the diameter of the rod and make the bushings using the measurements. We could have bushings that are loose fitting and tight fitting. For tight fitting bushings, we need to make the diameter larger than that of the rod by ~0.002in.

The class was very hands-on and interesting, and we learned a lot of useful techniques that I am excited to utilize for the next assignment!

Piano Wires

Our group first learned about using piano wires to attach two pieces of delrin together. Using a wire cutter, we cut piano wires of different diameters and learned to measure the diameters using a caliper. It was my first time using a digital caliper, so I thought it was very convenient compared to the non-digital ones. We also measured the diameter of the drill bits in order to determine what size we would use for a particular piano wire. Depending on how tight we want our wires to fit, we would adjust the size of the drill bits. Then, we were given the opportunity to try drilling a hole into a piece of delrin using the drill press and fitting a piano wire through the hole also using the drill press.

The piano wire technique is great for making hinges and joining corners. One precaution that we need to take when using this technique is to make sure that the holes are lined up perfectly and that the wire is mostly straight. Also, we need to be careful when using the drill press and slowly drill little by little.

Press Fit

The second technique we learned was press fitting. Press fitting is another technique that is used when joining delrin pieces together. We first need to measure the width of the delrin we are using with a caliper. For a tight fit, there notches need to accurately cut using the laser cutter and the height of the notches need to be about 0.005 inches taller than the width of the delrin. The fitting can be removed using pliers, but not easily with just bare hands.

My partner and I tried cutting small test pieces using the laser cutter, but our notches were too small. It takes very accurate measurements for the press fit to work perfectly, but it is one of the methods that require the least amount of technical work.

Heat Staking and Bushings

Lastly, we were introduced to heat staking and bushings.

Heat staking is simply melting the delrin onto another piece of delrin and attaching the two pieces together. Using a laser cutter, a square hole is cut onto a piece of delrin and another piece is cut so that there is a part that could fit through the square hole. Then, using a heat stake that is set to about 400 degrees F, we melt down the delrin until it is completely melted onto the other piece of delrin. Then we turn off the heat stake and use the air valve to cool down the delrin for about 50 seconds.

This is a great technique for joining pieces of delrin, but it would be difficult to join edges in an angle due to the nature of the machine.

In order to make our windless using rods, making bushings is an absolutely useful technique. Similar to the press fit, we need to measure the diameter of the rod and make the bushings using the measurements. We could have bushings that are loose fitting and tight fitting. For tight fitting bushings, we need to make the diameter larger than that of the rod by ~0.002in.

The class was very hands-on and interesting, and we learned a lot of useful techniques that I am excited to utilize for the next assignment!

Thursday, February 6, 2014

Making a Bottle Opener

For our first project, we were given a task of designing and making a bottle opener. It seemed like a fairly simple task at first, but to my surprise, we went through a lot of trial and error.

We first started out by brainstorming different ideas for the design. Christina and I came up with many different types of structures. We narrowed our choices down to 3, which included the following:

We decided to try out the trapezoidal bottle opener because it appeared very sturdy and seemed like it would work best out of our top 3 candidates. We also liked the idea of pushing down on the bottle opener rather than lifting it up to open the bottle because by pushing down, we are letting the body weight do the work instead of our arm muscles. In addition, we would use a greater area of our hand to push down the opener rather than lifting it up, which would decrease the amount of pressure applied to the hand.

Next step was making a life-size model of the bottle opener using foam core. It took three trials for the foam core model to look like what we envisioned. We wanted the design to be aesthetically pleasing, functional, and easy to use/hold.

When designing our models, we took into consideration various physical properties. In class, we learned about deflection, which is the measurement of how much a material displaces under the presence of force. For a cantilever with a fixed end, the equation of deflection is as follows:

Day 1

We first started out by brainstorming different ideas for the design. Christina and I came up with many different types of structures. We narrowed our choices down to 3, which included the following:

|

| Fig 1. Initial Ideas for the Bottle Opener |

Next step was making a life-size model of the bottle opener using foam core. It took three trials for the foam core model to look like what we envisioned. We wanted the design to be aesthetically pleasing, functional, and easy to use/hold.

|

| Fig 2. Foam Core Models |

When designing our models, we took into consideration various physical properties. In class, we learned about deflection, which is the measurement of how much a material displaces under the presence of force. For a cantilever with a fixed end, the equation of deflection is as follows:

Deflection=(FL^3)/(3EI)

F=Force

L=Length of the beam

E=Young's Modulus

I=Area Moment of Inertia

F=Force

L=Length of the beam

E=Young's Modulus

I=Area Moment of Inertia

According to the equation, we know that making length long would cause a lot of deflection. I also took torque into consideration because the bottle opening motion is essentially rotating the opener around a fixed axis. With a given amount of torque, if the distance between the axis and and the force (or the point where the force is applied) is bigger, we can rotate the object with less force and vice versa. Therefore, we did not want the length of the bottle opener to be too short either.

In terms of material, we decided to use the 1/8 inch delrin because we found it sufficiently strong for our purposes.

In terms of material, we decided to use the 1/8 inch delrin because we found it sufficiently strong for our purposes.

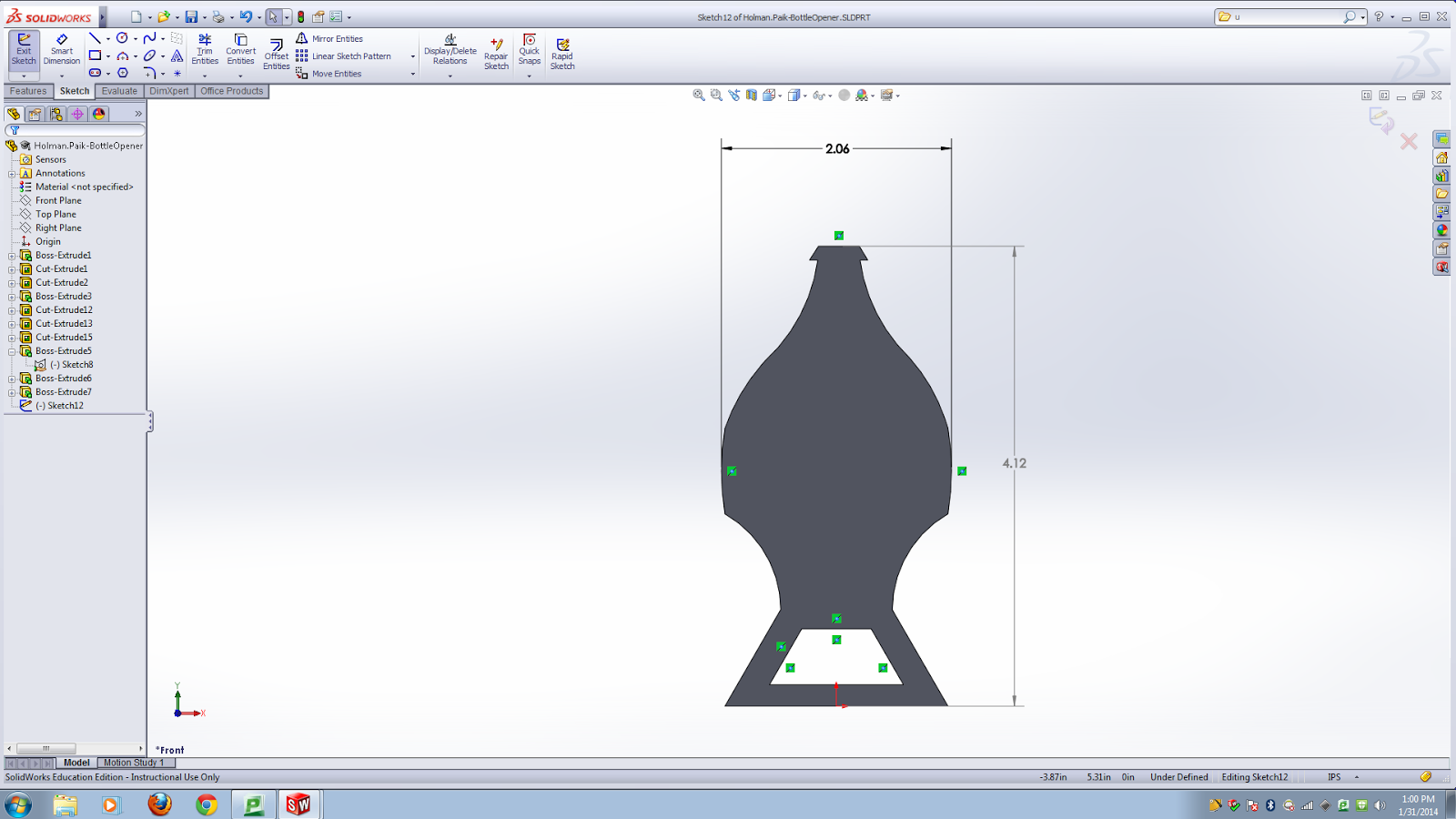

Day 2

Using the foam core model as a reference,we started to draw our design using solid works. This process required a lot of patience because it was my first time using the software. Eventually, I learned a lot of different commands and features of the software and it made the drawing process easier and faster.

After we drew the sketch, we changed the color of the lines to indicate what lines required cutting verses etching.

|

| Fig 3. Solid Works Drawing of the First Bottle Opener |

Day 3

We spent most of the second class meeting trying to print our drawing using the laser cutter. During our first try, the laser was running through the cuts multiple times, which made the delrin melt. Also, the etchings were not too visible.

Then, we found out that making a PDF version of our drawing could facilitate the cutting process, so we made the PDF file and was able to successfully cut our bottle opener.

|

| Fig 4. Finished Product of the First Bottle Opener |

We tested our bottle opener to see if it was able to open the bottle cap. It took several tries, but with some effort, we could get it to open.

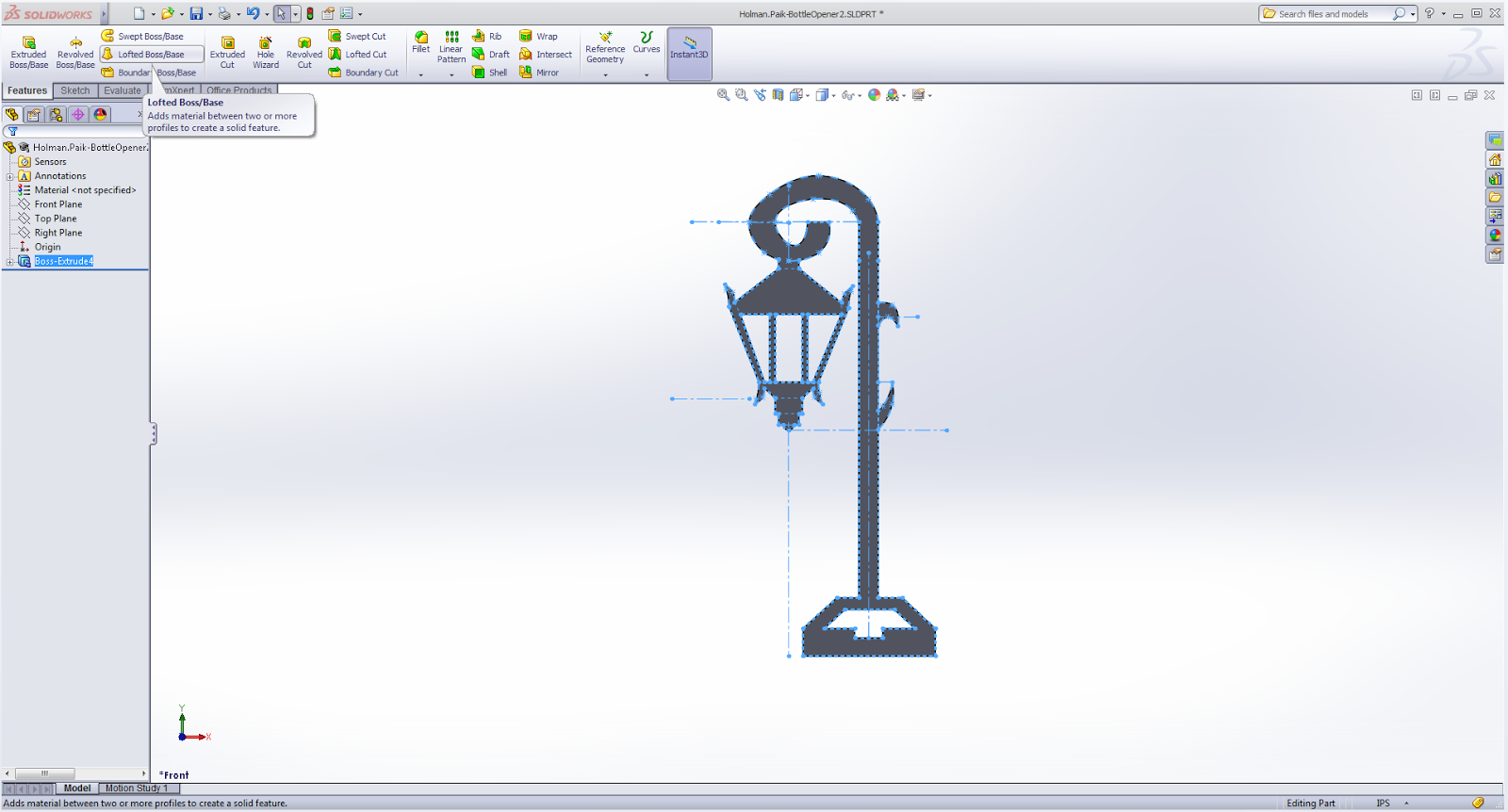

Day 4

For our second bottle opener, we decided to change our design so that it would be more aesthetically pleasing and functional. We decided to make the opening on our bottle opener narrower so it would be caught onto the bottle cap and provide more leverage. We also decided to change the design so that it would resemble a Wellesley lamp post. Lastly, we wanted to add an additional bottle opening mechanism that would hook the bottle cap and lift it up.

|

| Fig 5. Rough Sketch of the Second Design |

|

| Fig 6. Solid Works Drawing of the Second Bottle Opener |

Day 5

During the class period, we cut out our second bottle opener. However, the dimensions were off and some of the parts broke off.

|

| Fig 7. Final Product of the Second Bottle Opener |

We found out that we needed to make our design more structurally sound. Also, we found out that our drawing was being transferred as a 1:2 ratio which altered our dimensions. We redesigned our bottle opener for the third time.

| |

| Fig 8. Final Bottle Opener Design |

Day 6

We cut out our final bottle opener design using a 3/16 inch delrin. We tested the product to see if would open the bottle. Using the hook mechanism, the bottle opened successfully.

| |

| Fig 9. Final Product of the Third Bottle Opener |

Final Thoughts:

It was surprising to learn that making a simple device such as a bottle opener required a lot of trial and error. Even though we took physics into account when making our design,the actual product did not seem to utilize the laws of physics that we had considered. If we could have another chance, I would want to create a very sturdy design that could open the bottle with more ease.

Subscribe to:

Comments (Atom)